(1)_1767881464.webp?x-oss-process=image/format,webp)

(1)_1767881464.webp?x-oss-process=image/format,webp/resize,l_40)

(1)_1767881464.webp?x-oss-process=image/format,webp/resize,l_40)

(1)_1767881464.webp?x-oss-process=image/format,webp/resize,l_40)

(1)_1767881464.webp?x-oss-process=image/format,webp/resize,l_40)

_1767881464.webp?x-oss-process=image/format,webp/resize,l_40)

_1767881463.webp?x-oss-process=image/format,webp/resize,l_40)

_1767881464.webp?x-oss-process=image/format,webp/resize,l_40)

(1)_1767881465.webp?x-oss-process=image/format,webp/resize,l_40)

- Rib-Peeling Threading Roller Machine Type : BTCP-40-100 Processing range:16-40 (for processing 12-14 and 50, a separate machine head is required). Processing length of steel bars :200mm for right-handed thread, 80mm for left-handed thread (customization is required for processing lengths above 200) Main motor power:7.5KW Power supply: three-phase 440V 60HZ Spindle speed: 62-63r/min 1:23 Weight: 450kgs/Set Size :1170*550*1020mm Threading Roller :Semicolon

Rib-Peeling Threading Roller Machine BTCP Type

Product Characteristic

| Part Name: | Rib-Peeling Threading Roller Machine | Rib-Peeling Threading Roller Machine | Rib-Peeling Threading Roller Machine | Rib-Peeling Threading Roller Machine |

| Machine Type: | BTCP-16-40 -100 | BTCP-16-40 -200 | BTCP-16-40 -300 | BTCP-16-40 -500 |

| Process rebar : | D16-D40 | D16-D40 | D16-D50 | D16-D40 |

Process rebar length(mm): | 100mm | 200MM | 300MM | 500MM |

| Power supply: | 3P/380V /50HZ/60HZ | 3P/380V /50HZ/60HZ | 3P/380V /50HZ/60HZ | 3P/380V /50HZ/60HZ |

Main motor power(kw): | 7.5KW | 7.5KW | 7.5KW | 7.5KW |

| Machine Size(mm): | 1170*550*1020mm | 1200*650*1020mm | 1200*650*1020mm | 1200*850*1020mm |

| Weight Kgs/set kgs | 400Kgs/Set | 450Kgs/Set | 500Kgs/Set | 650Kgs/set |

| Note : Support Customizable Services | ||||

| ||||

Introduction:

This machine processes high-precision straight threads on steel bar ends using a "peel then roll" method. The threads work with matching sleeves to form mechanical connections. A mainstream technology after cold-squeezing, it is widely used for its efficiency, energy savings, precise threads, and strong connections. |

Product Advantage:

|

Matched Machine

Rib-Peeling Threading Roller Machine HGS

|

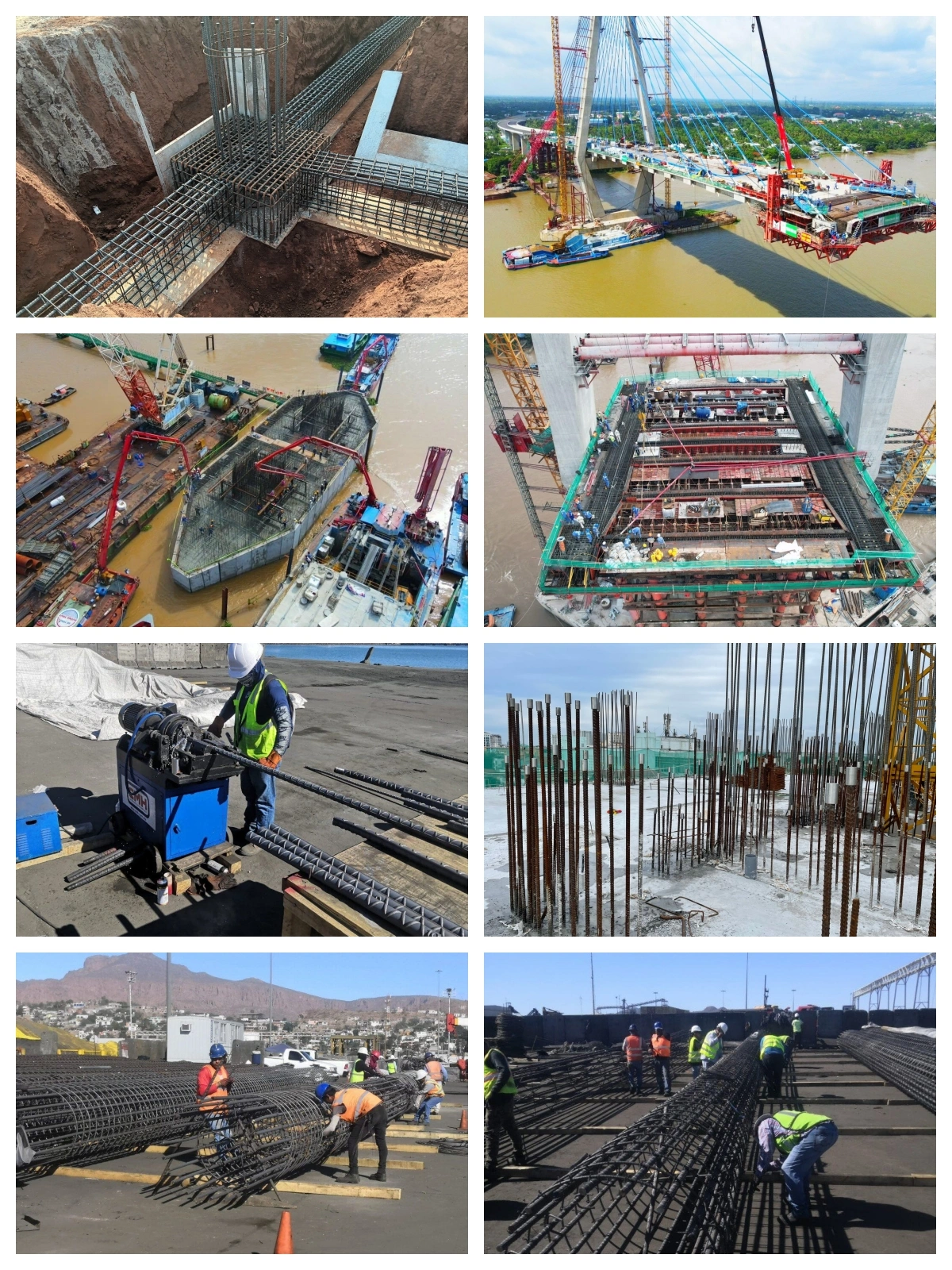

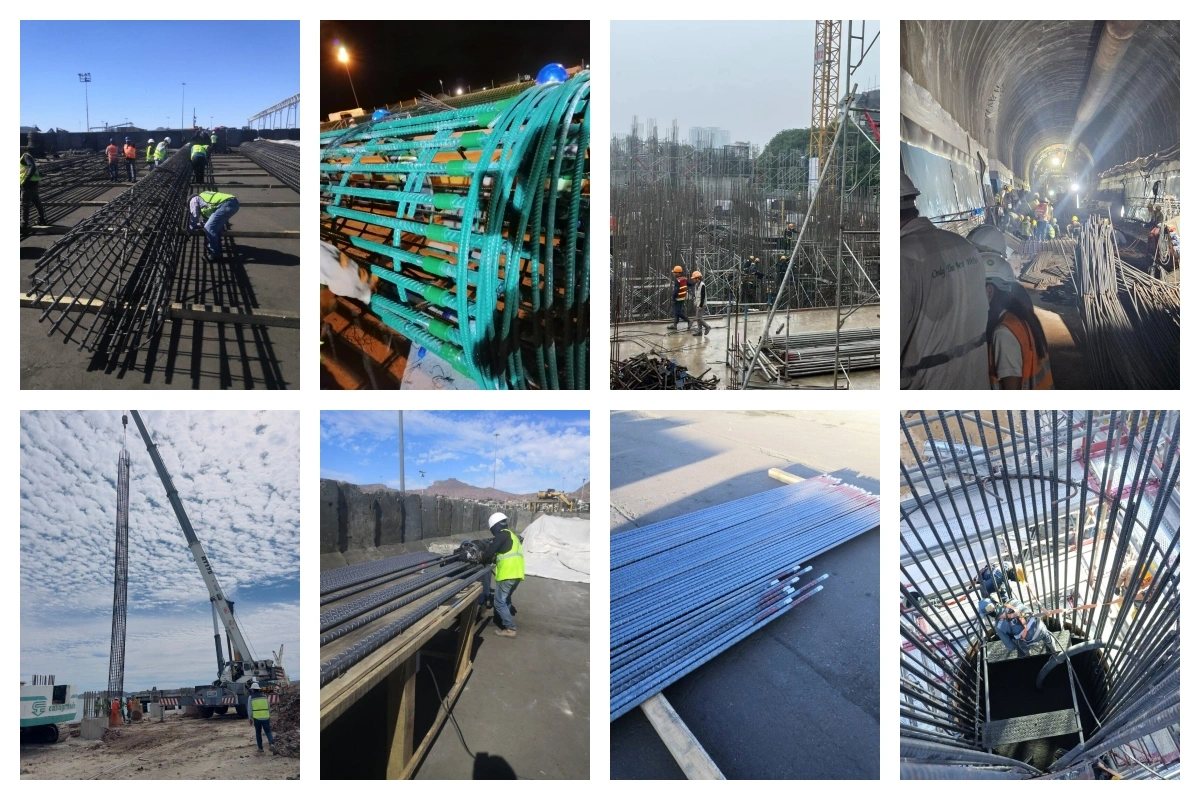

Project Picture

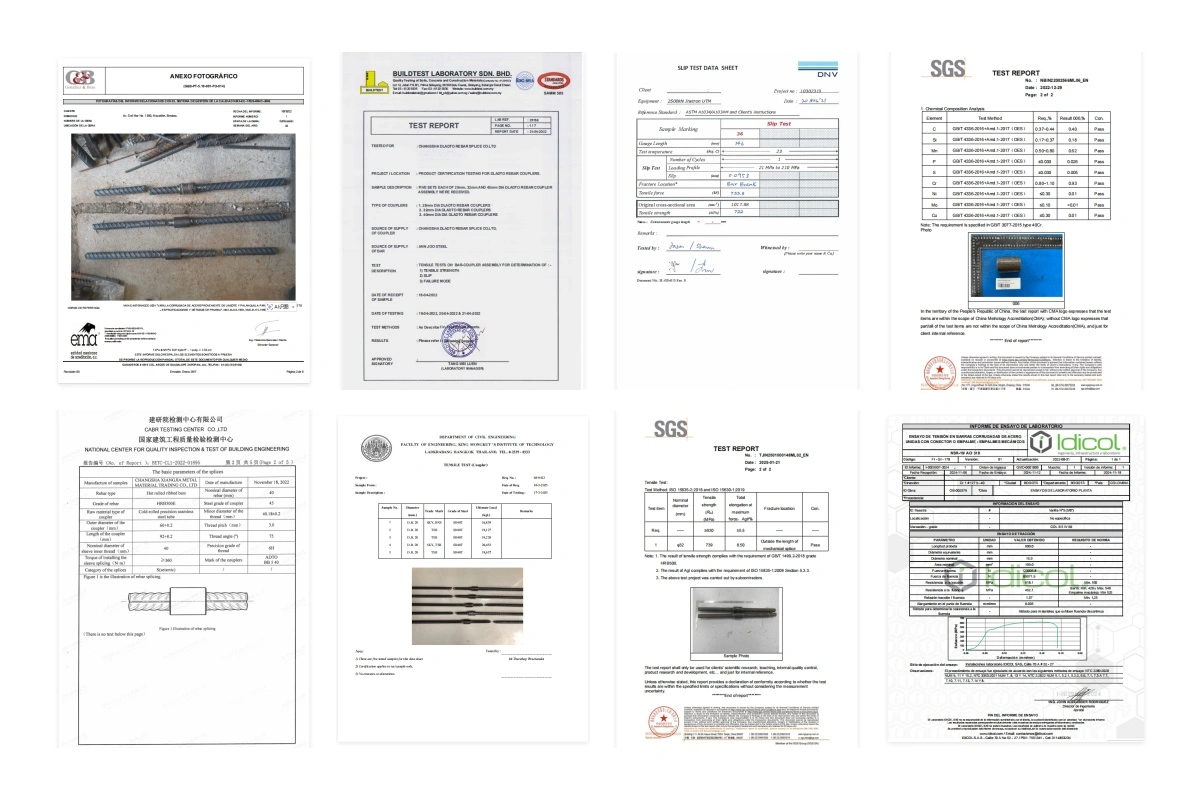

Certification

Test Picture

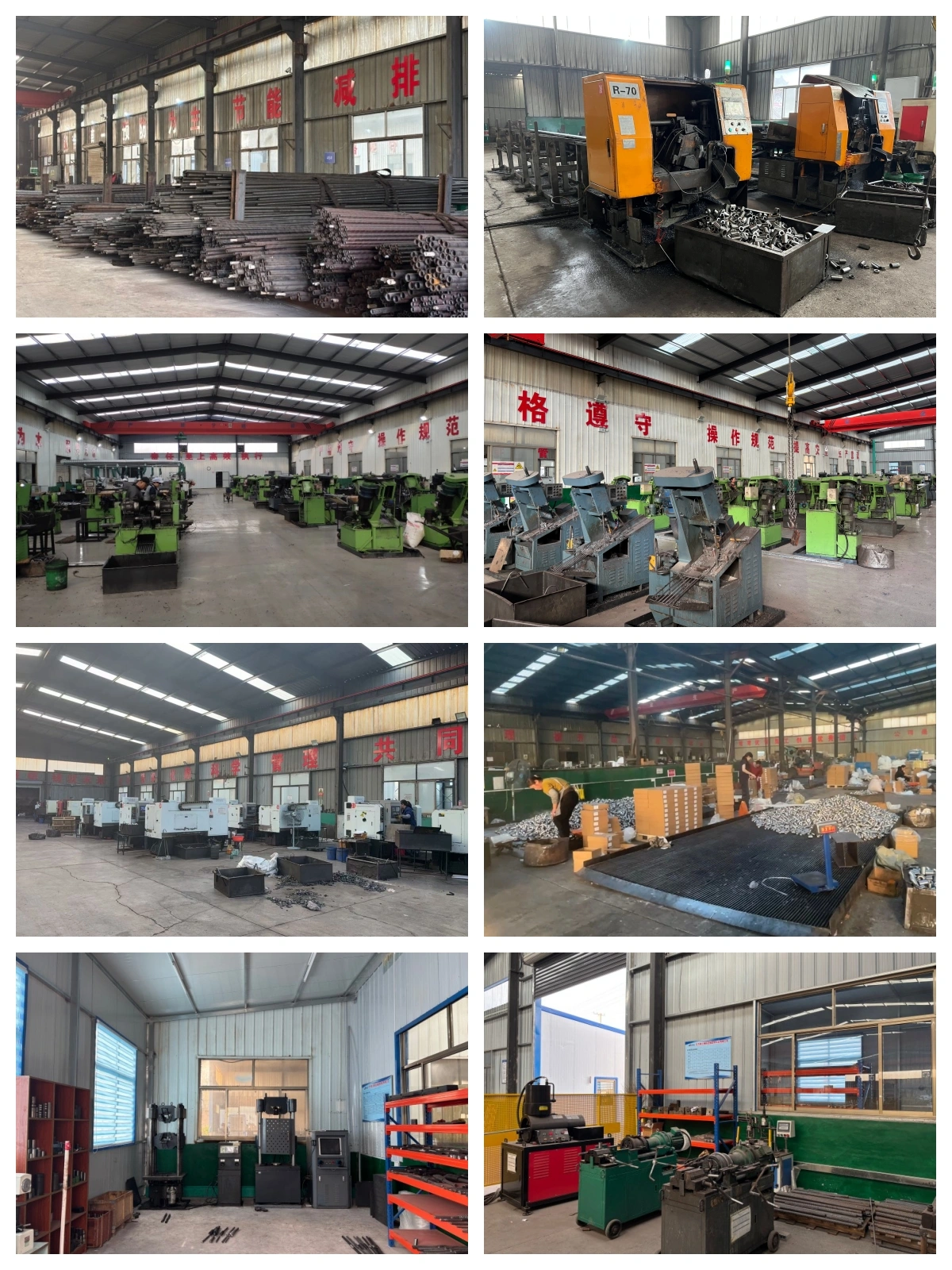

Factory Picture

Package

|

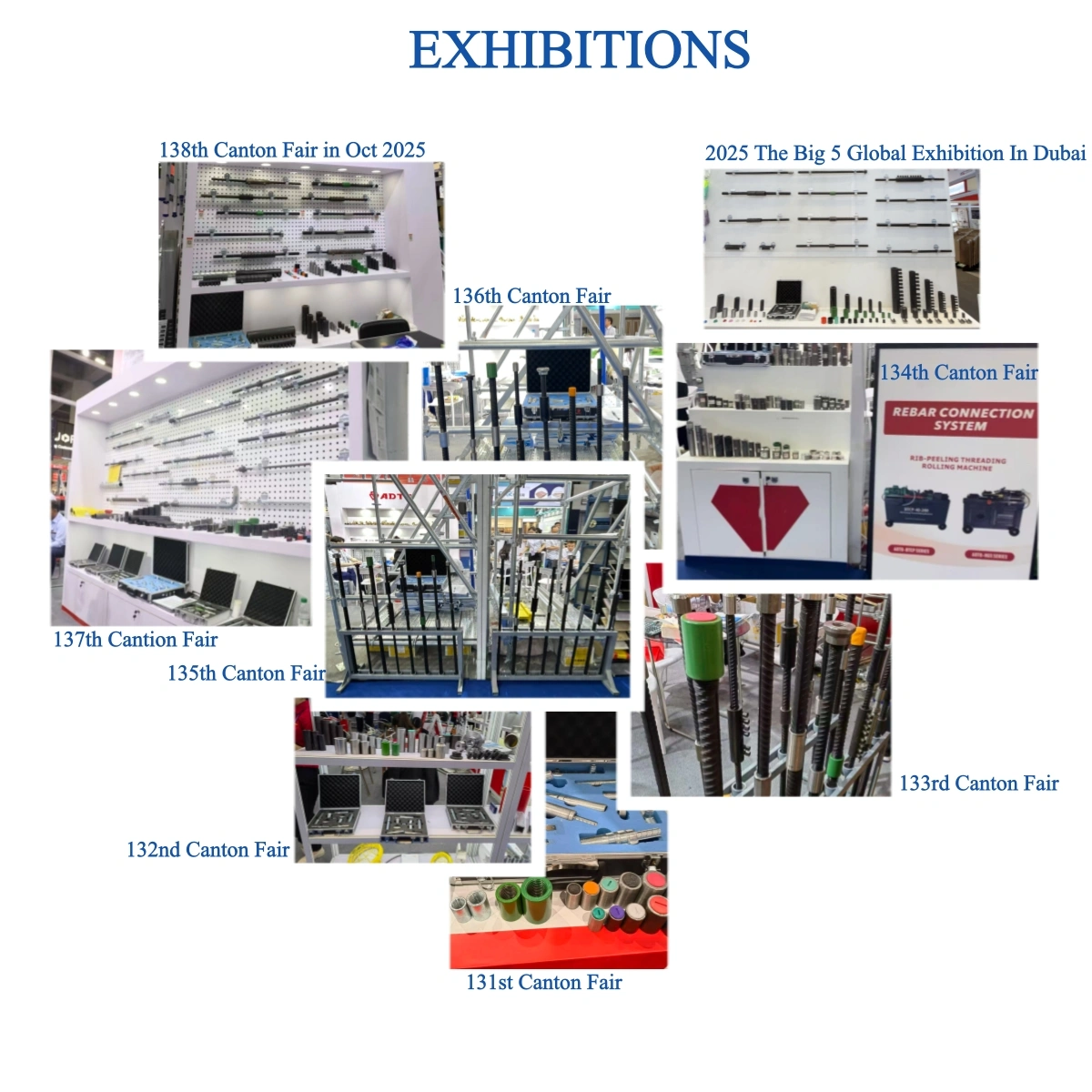

Fair Information

(1)_1767881464.webp)

(1)_1767881464.webp)

(1)_1767881464.webp)

(1)_1767881464.webp)

_1767881463.webp)

_1767881464.webp)

_1767881463.webp)

_1767881464.webp)

(1)_1767881465.webp)